The material PEEK is a unique, versatile, semi-crystalline engineering thermoplastic with excellent chemical resistance. Due to its high heat distortion and temperature resistance, components can be used at temperatures up to 250 – 260 °C. The melting point of the high-temperature plastic is approx. 341 °C.

The material is often used in environments with hot water or steam and is still able to maintain its physical properties such as flexural strength and tensile strength at a high level.

Polyetheretherketone is often mistaken as just a high-priced engineering thermoplastic. However, experienced users appreciate the added value that PEEK plastics offer due to their desirable material properties; that is, the ability to produce components that are lighter, more resilient and can withstand demanding operating conditions over a longer period of time.

A major advantage of PEEK plastic is that the material properties can be adjusted to suit the application. Various modifications are available, such as fiber reinforced PEEK, PEEK with PTFE, conductive PEEK and others. You can choose the most suitable material depending on the environment and area of use. We also offer special material types for medical, oil and gas, semiconductor, agricultural, food and aerospace applications.

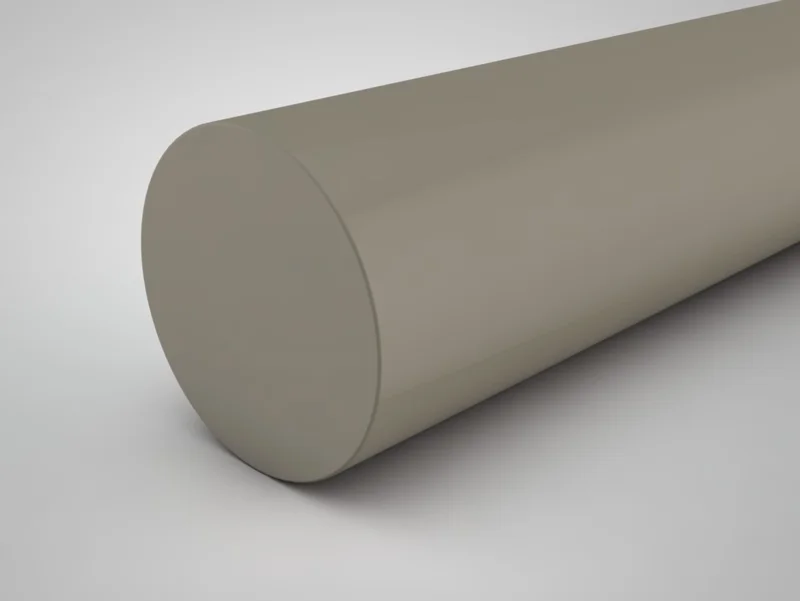

We deliver in Bolt, plate and blank pipe. If you need machined parts, you can contact us via the contact form.