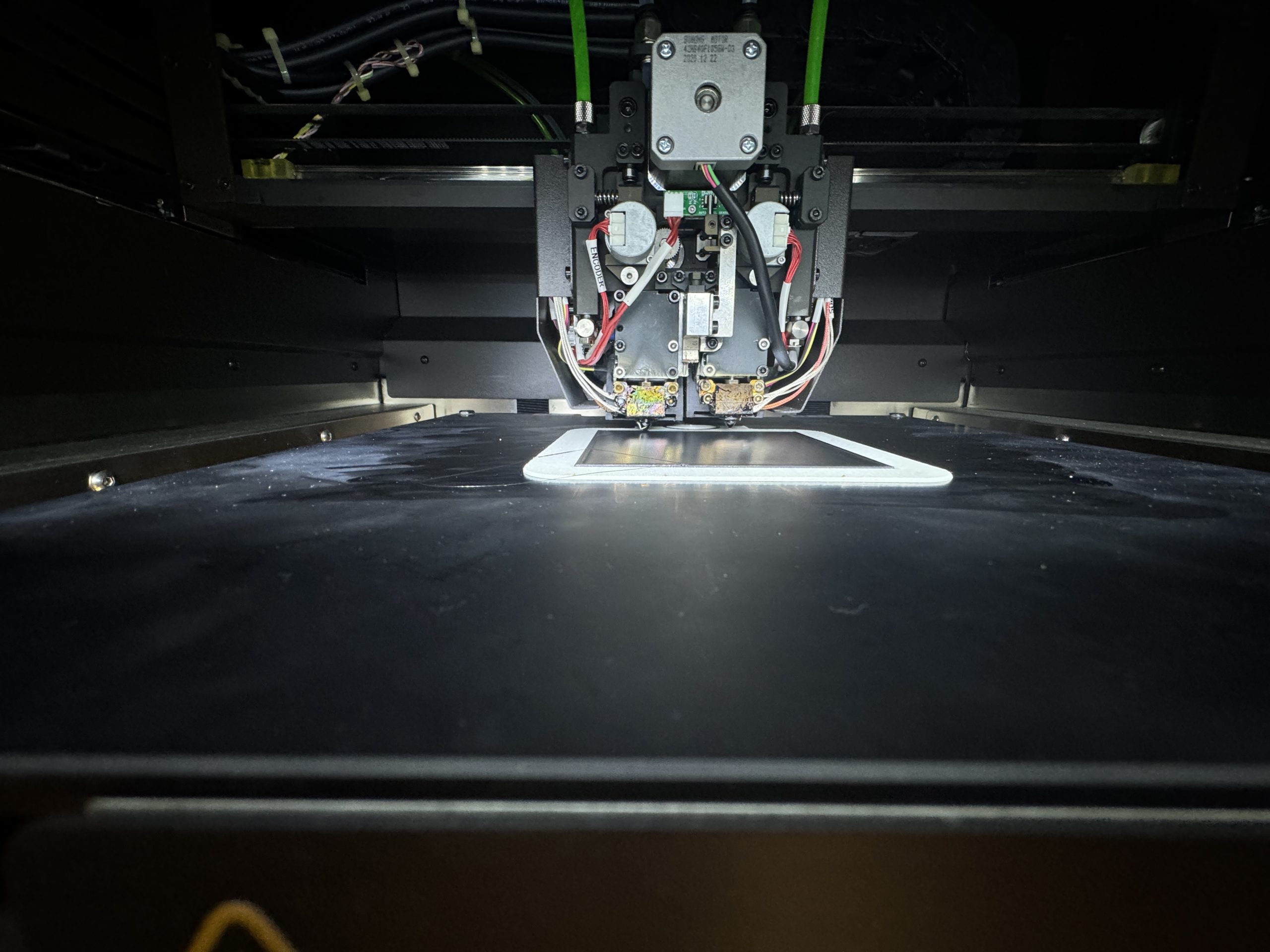

In the rapidly evolving industrial landscape, 3D printing is playing an increasingly central role in technical manufacturing. This revolutionary technology offers a number of benefits that can optimize manufacturing processes, reduce costs and shorten development time. Scanco AS, a leading player in mechanical processing and manufacturing services, is harnessing the full potential of 3D printing to deliver tailor-made solutions to its customers. In this article, we explore five key benefits in technical manufacturing, and how this technology can provide significant benefits to your business.

1. Flexibility in design and production

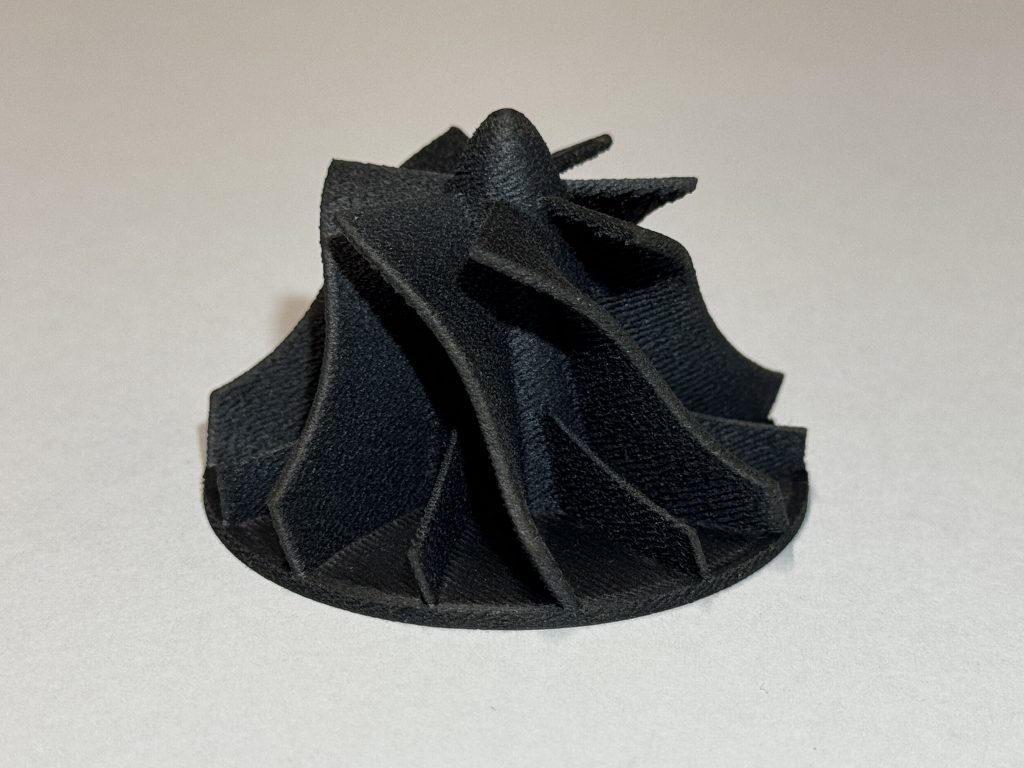

One of the biggest advantages is the incredible flexibility it offers in design and manufacturing processes. Traditional manufacturing methods, such as machining, often require complex tooling and expensive setups to produce detailed parts. With this technology, complex geometries and intricate details can be realized without the need for specialized tools. This allows for greater creativity and innovation in the design phase, which is especially valuable in the development of prototypes and unique components.

Scanco AS offers advanced 3D printing providing precise and complex components tailored to your needs. This flexibility allows engineers and designers to experiment with new concepts without limitations, which can lead to better products and faster innovation.

2. Cost savings and efficiency

This method has proven to be a cost-effective solution, especially when it comes to small and medium-sized production runs. Traditional manufacturing methods can be expensive to set up for small runs due to high tooling costs and longer production times. 3D printing eliminates the need for expensive tooling and allows for rapid production of parts without large upfront investments.

Industry often chooses this method over machining because of these cost savings. By reducing material waste and production time, companies can achieve significant savings. Scanco AS can help you cut costs and development time through efficient 3D printing solutions tailored to your specific needs.

3. Reduced development time

In competitive markets, time is often a critical factor for success. 3D printing enables rapid production of prototypes, significantly speeding up the development cycle. By being able to produce and test prototypes quickly, companies can identify and correct errors earlier in the development process, leading to faster product launches.

Scanco AS offers fast and cost-effective prototypes as well as high-quality products ready for use in end-use applications. This efficiency in the development phase gives companies the opportunity to get to market faster with innovative products, which provides a competitive advantage.

4. Material flexibility and advanced properties

3D printing offers the ability to use a wide range of materials, from simple polymers like PLA to advanced materials like PEEK. This makes it possible to produce parts with specific properties such as high temperature tolerance, chemical resistance or increased strength. The material flexibility allows for the production to be tailored to exact requirements and specifications, which is essential for technical manufacturing.

Scanco AS offers services within 3D printing and 3D modeling, and can print in a wide range of materials. Whether you need parts that can withstand extreme temperatures or require high mechanical robustness, Scanco AS can deliver materials that suit your needs.

5. Sustainability and environmental friendliness

Environmental concerns are becoming increasingly important in industry, and this technology can contribute to more sustainable production processes. Traditional production methods can generate significant material waste, while 3D printing builds parts layer by layer, minimizing excess materials and waste. In addition, this method can optimize transportation and logistics by producing parts closer to the end user, reducing the carbon footprint.

Scanco AS's 3D printing solutions are designed to minimize material waste and optimize production processes, making them an environmentally friendly choice for modern industry. By choosing 3D printing, your company can contribute to a more sustainable future without compromising on quality or performance.

Why is industry choosing 3D printing over machining?

Industry often chooses this method over traditional machining due to the aforementioned advantages. 3D printing provides greater design flexibility, reduces costs and development time, and offers material flexibility that is difficult to match with machining. In addition, the ability to produce complex geometries and adapt production quickly makes it appealing to modern manufacturing needs. Scanco AS's advanced 3D printing technology ensures that you get precise, durable and tailored solutions that meet your technical requirements.

What is 3D printing suitable for in small and medium-sized series?

This technology is particularly well suited for small and medium-sized production runs. When you don't need mass production but still want high-quality parts, 3D printing is an ideal solution. It allows flexible manufacturing and makes it possible to change designs quickly without high tooling and setup costs. This is especially useful in industries where product development is rapid and requires frequent adjustments and updates.

Scanco AS can help your company utilize 3D printing for small and medium-sized series, thereby ensuring that you can scale production as needed without large capital costs.

How do you cut costs and development time with 3D printing?

3D printing cuts costs and development time in several ways. First, it eliminates the need for expensive tooling and setup that traditional manufacturing requires. This significantly reduces start-up costs, especially for small series and prototypes. In addition, 3D printing minimizes material waste by building up parts layer by layer, resulting in lower material costs.

Furthermore, it speeds up the development process by enabling rapid production and testing of prototypes. This reduces the time it takes to bring a product from idea to finished product, giving companies the ability to respond more quickly to market changes and customer demands. Efficient processes ensure that you can reduce both costs and development time, while maintaining high quality and precision.

Advanced 3D printing with Scanco AS

Scanco AS offers advanced manufacturing solutions that provide precise and complex components tailored to your needs. Our range of materials, from PLA to advanced PEEK, makes it possible to find the perfect solution for your application. We offer both rapid prototypes and production-ready products, ensuring you get the functionality and durability you need.

For more information about our 3D printing and 3D modeling services, visit our page about 3D Printing – Advanced Prototyping And ManufacturingContact us to discuss how we can help you optimize your production processes.

Conclusion

3D printing is revolutionizing technical manufacturing by offering flexibility, cost savings, faster development time, material flexibility and sustainable solutions. Scanco AS is ready to help your company exploit these benefits through our advanced 3D printing services. By integrating this technology into your production processes, you can achieve higher efficiency, reduce costs and lead in innovation. Explore the possibilities with Scanco AS, and contact us to find out how we can support your business with our tailored 3D printing solutions.