Manual measurements are time-consuming and prone to errors – modern manufacturing companies know this. With 3D scanning you get extremely accurate target control, rapid digital modeling and a seamless path from idea to finished product. Scanco AS offers advanced technology that gives the industry an effective advantage. Here you will find out how.

Do you want to reduce error margins and streamline production? Then you should consider 3D scanning as a permanent part of your production flow.

How does it work in practice?

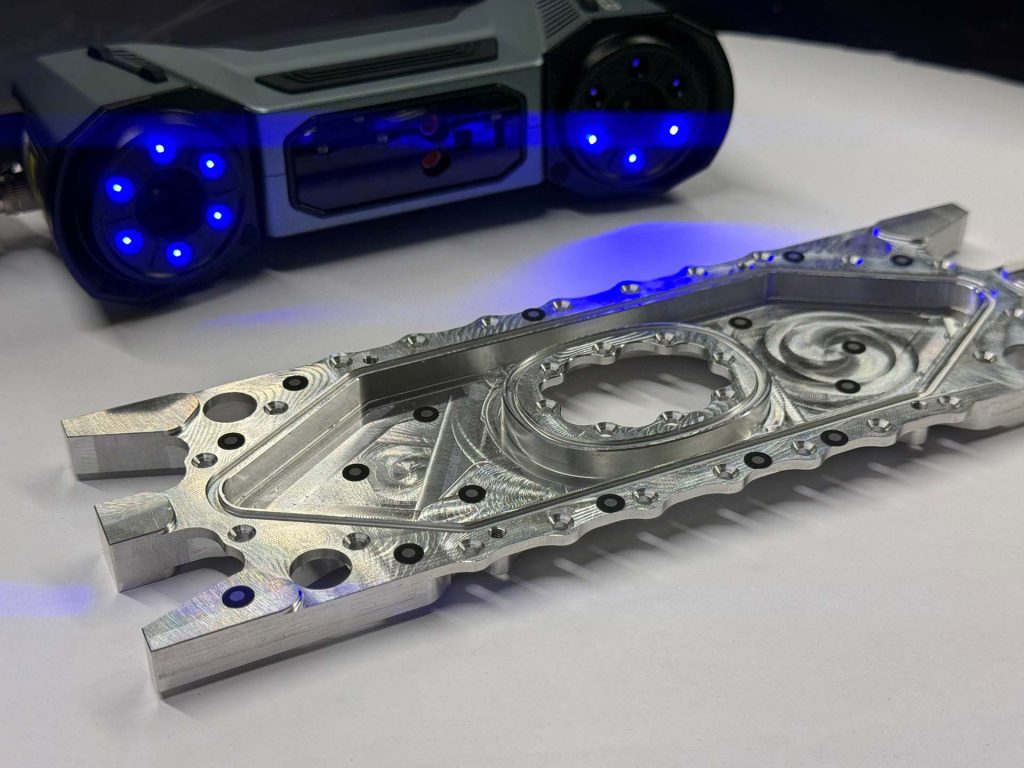

Laser-based 3D scanning is a technology that uses laser beams to capture detailed digital representations of physical objects. The process begins with a 3D scanner emitting laser light onto the surface of an object. When the laser beam hits the object, it is reflected back to the scanner, which records the time it takes for the light to return. This information is used to calculate the distance between the scanner and the object, providing highly precise coordinates.

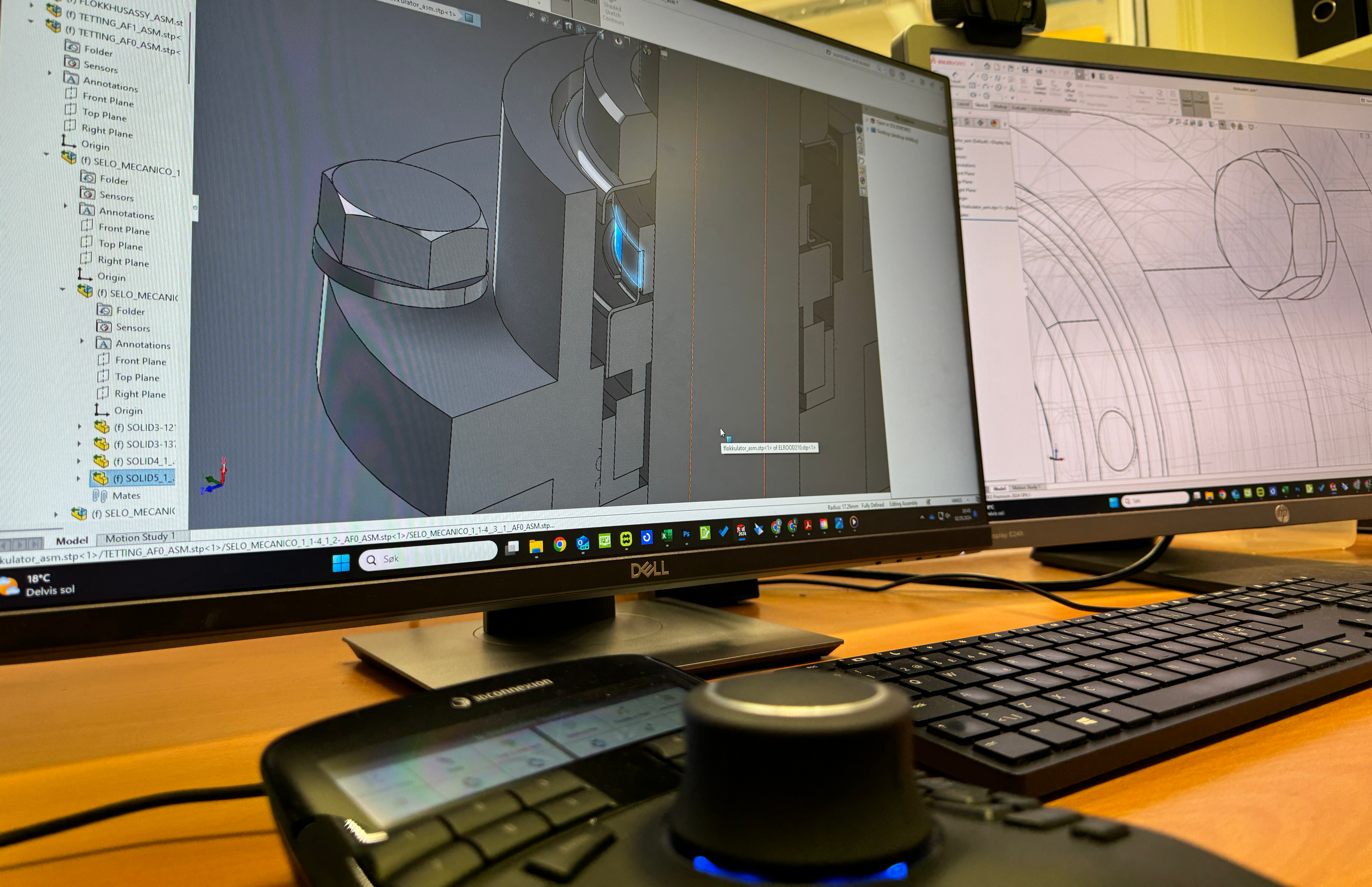

Scanco AS's 3D scanning technology can scan both small and large parts with an accuracy of hundredths of a millimeter. This makes it possible to capture even the smallest details, which is essential for high precision in manufacturing processes. After scanning, the data is processed by advanced software that converts the measured points into a digital 3D model. This model can then be used for further analysis, inspection or as a basis for the production of new parts.

What are the advantages of 3D scanning versus manual measurement?

The transition from manual measurement to 3D scanning offers a number of benefits that can transform manufacturing processes. One of the most obvious benefits is precision. While manual measurement relies on operator skill and can be prone to human error, laser-based 3D scanning ensures consistently accurate results every time. This is especially important in complex or critical applications where tolerances are tight.

Another advantage is efficiency. Manual measurement can be time-consuming, especially when it comes to detailed or complex components. 3D scanning can quickly collect extensive data, significantly reducing the overall measurement and inspection time. This leads to shorter production cycles and increased productivity.

Additionally, 3D scanning provides the ability to analyze and visualize data in a way that is not possible with manual measurement. Digital 3D models can be easily shared and collaborated on across different departments or geographic locations, improving communication and decision-making throughout the manufacturing process.

Typical applications in mechanical industry and prototyping

3D scanning has a wide range of applications in the mechanical engineering and prototyping industries. One of the most prominent applications is reverse engineering, where existing components are scanned to create detailed digital models. This is particularly useful when original drawings are missing or when existing parts need to be reproduced or modified.

In quality control, 3D scanning is used to compare manufactured parts to their digital design models. This ensures that each component meets the required specifications and standards, and helps identify and correct any manufacturing errors early in the process. The result is higher product quality and a reduced risk of defects in the final product.

Prototyping is another important area where 3D scanning plays a critical role. By scanning physical prototypes, engineers and designers can quickly iterate and improve their designs without the need for extensive manual measurement and modeling. This leads to faster development times and more innovation, as ideas can be tested and improved in a digitally simulated environment before being implemented in physical production.

Scanco AS: Your partner for precise 3D scanning and efficient production

Scanco AS is a leading supplier of 3D scanning services in Norway, offering comprehensive solutions that help industrial companies improve their production processes. With advanced 3D scanners and software, Scanco AS can scan a wide range of parts with high accuracy, ensuring precise measurement control and efficient production.

In addition to 3D scanning, Scanco AS also offers 3D modeling services. Whether you have an existing product or just an idea, their experts can develop accurate digital models that can be used for further analysis, prototyping or manufacturing. This gives customers the flexibility to customize and optimize their products to specific needs and requirements.

By partnering with Scanco AS, companies can benefit from a combination of advanced technology, expertise and tailored solutions designed to meet the unique challenges of today's industrial environments. Their dedication to quality and customer service makes them an ideal partner for anyone looking to implement 3D scanning in their manufacturing processes.

Conclusion

3D scanning represents a significant advancement in dimensional control and manufacturing efficiency. With its ability to deliver accurate, detailed digital models quickly and efficiently, 3D scanning outperforms traditional manual measurement methods in several key areas. Scanco AS's expertise in 3D scanning provides industrial companies with access to reliable and accurate solutions that can transform their manufacturing processes. Explore the benefits of 3D scanning and discover how it can improve your industrial operations by contacting Scanco AS today.