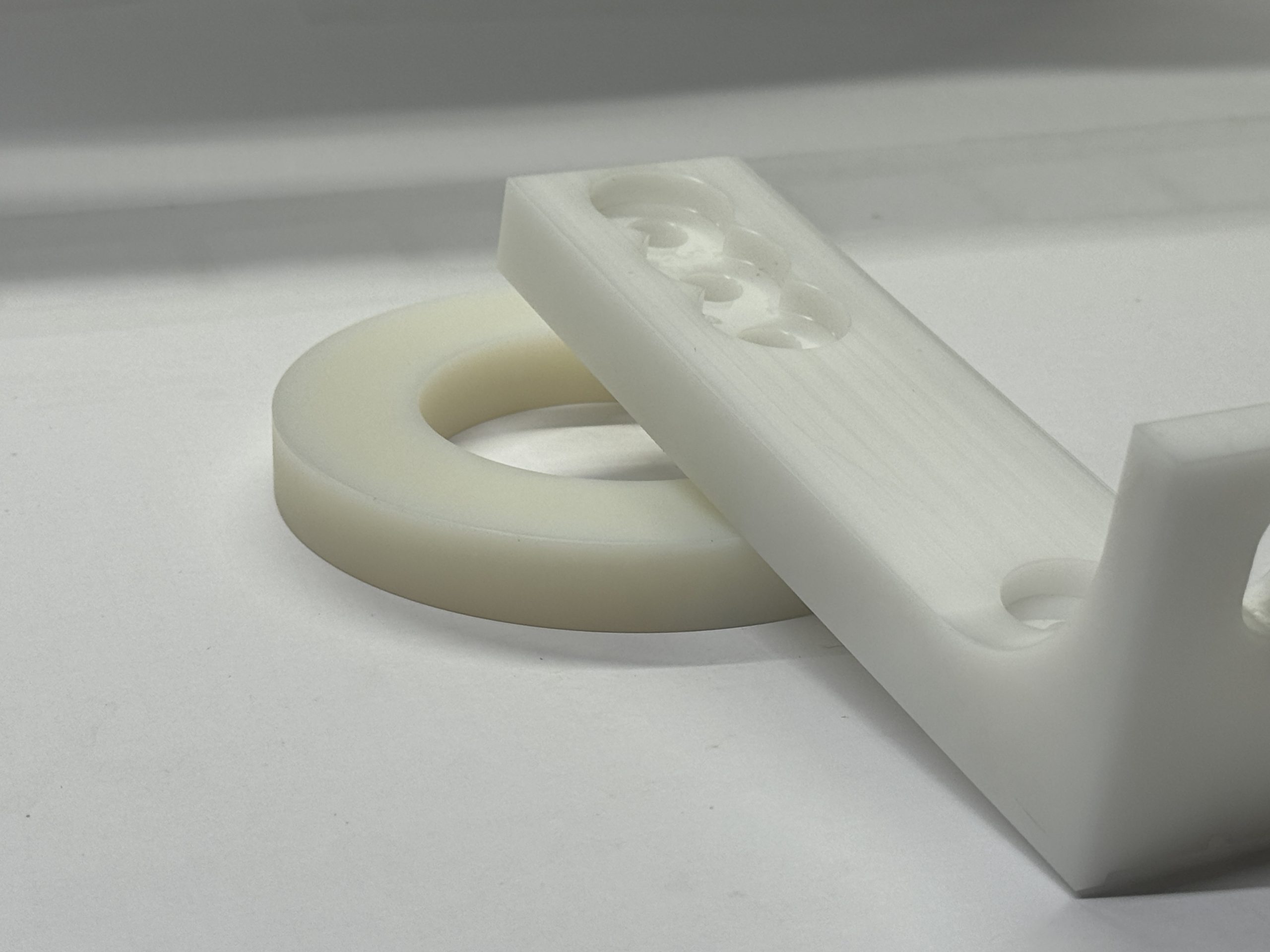

Explore our selection of PEHD 1000, also known as high density polyethylene, and experience the solid quality that this thermoplastic material brings to your projects. The material has impressive strength, chemical resistance and versatility, making it the optimal choice for industrial applications where robustness and reliability are essential.

Highlights:

Extreme Abrasion Resistance: PEHD 1000 has extremely good wear resistance, and provides reliable solutions for areas with high mechanical stress.

Chemical Resistance: With its impressive chemical resistance, it is suitable for use in environments with exposure to various chemicals.

Low Friction: PEHD 1000 has low friction, making it ideal for applications that require smooth movement and reduced wear.

Good machinability: This material is easy to process and offers flexibility for customization to the specifications of your projects.

Areas of use:

The material is suitable for a variety of applications, including:

- Transport and storage equipment: PEHD 1000 is often used for the production of conveyor belts, screws and bearing components.

- Containers and Tanks: The chemical resistance makes PEHD 1000 suitable for the production of containers and tanks for various industrial purposes.

- Sliding and Guide solutions: Low friction makes PEHD 1000 ideal for the production of sliding and guiding solutions in machines and equipment.

CONTACT US

To find out more about our products, or to discuss specific requirements for your business, please feel free to contact us. We look forward to being your reliable partner in technical plastics.

CUSTOM MACHINED PARTS

If your needs include custom made and machined parts, we are your trusted partner. Our experienced team works with you to deliver tailored solutions that fit your exact requirements. Contact us easily through our practical contact form to start the dialogue about your projects and needs.