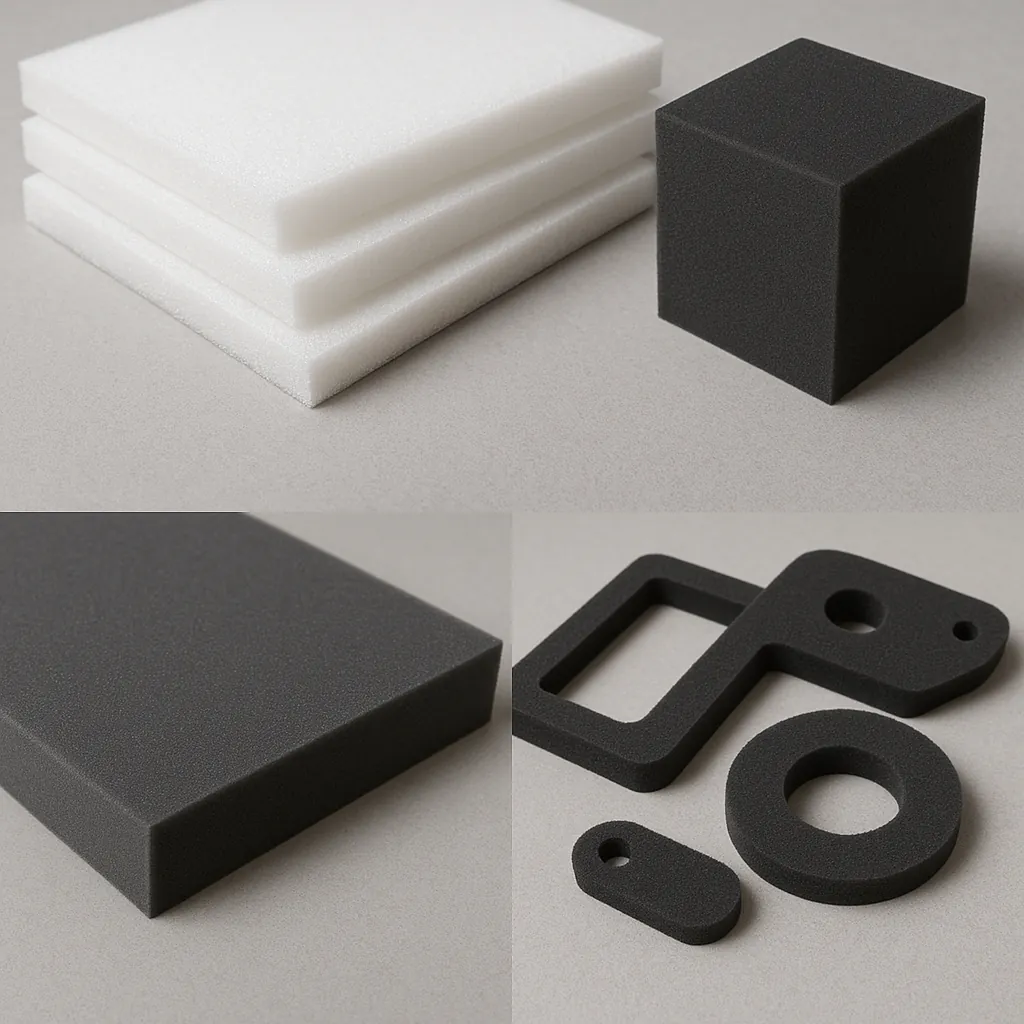

Cellulose plastic cut to size

Scanco AS supplies cellular plastic and foam plastic cut to customer specifications. We produce gaskets, inserts, insulation parts and special components in various types of foam, adapted to both prototypes and series production. Our production includes water cutting and other precision machining that provides clean edges and accurate tolerances.

Materials

We offer several types of cellular plastic and foam plastic, depending on the area of application and requirements for density, stiffness and surface.

PE foam (polyethylene)

A lightweight, closed-cell material with good strength and shock-absorbing properties. Well suited for inserts, packaging, structural parts and technical components. PE foam gives very neat cuts when waterjet cutting and is suitable for precision cutting.

EVA foam

A more robust and dense material than PE foam, available in a variety of colors and thicknesses, this type of foam is often used for inserts, boxes, tooling, and other areas that require higher rigidity and durability.

PU foam

Softer and more flexible material used where vibration damping or extra protection is needed. Well suited for packaging, internal components and cushioning materials.

PVC cellular rubber

A closed-cell material with good sealing properties and high chemical resistance. It is common in gaskets, weatherstripping and marine and industrial applications, and can be supplied with or without a self-adhesive backing.

Production and processing of cellular plastic

We customize foam plastic to your measurements, drawings or 3D models, and can therefore offer flexible solutions regardless of volume. Production can include:

Waterjet cutting for high precision and clean cuts

Carving complex contours

Series from single part to larger production volumes

Repetitive production with fixed templates

Adaptation according to CAD files, DXF, STEP or scanned models

Typical deliveries

We supply foam plastic for a variety of purposes in industry and technical applications, including when there is a need for:

Gaskets and seals

Tool foam and insert materials

Transport box insert

Protective and shock absorbing elements

Molded parts and technical components

Insulating elements and spacers

Advantages of foam plastic

Fast production time and high flexibility

Precise machining with clean edges

Wide range of materials and thicknesses

Suitable for both one-piece and series production

Modern production with waterjet cutting and digital modeling

Inquiry and quotation

Send us your drawing, measurements or sketch and we will produce according to your specifications. We are also happy to help with material selection and technical recommendations. Contact us here for a quick response.