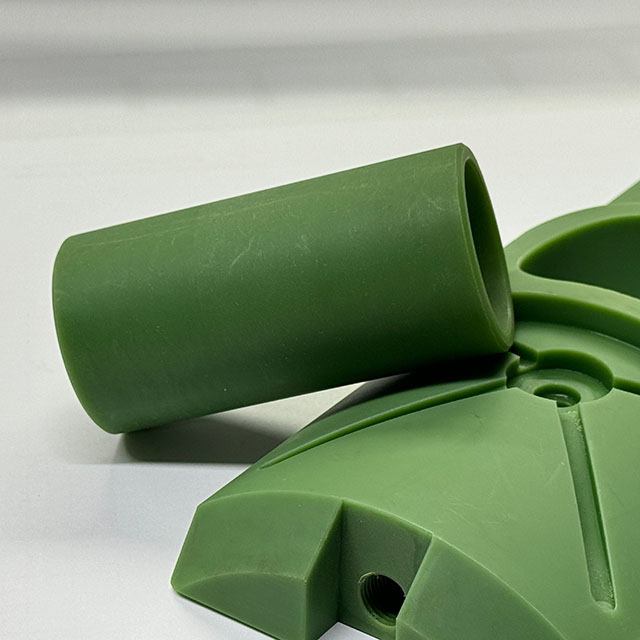

PA6 (Polyamide 6) is a thermoplastic material with high strength, abrasion resistance and flexibility. This versatile combination makes PA6 an ideal choice for demanding industrial applications, where components must withstand high loads over long periods of time.

Typical applications

PA6 is suitable for the production of machine components, gears, bushings and conveyors. The material retains its mechanical properties even under demanding conditions with high friction and varying temperatures. This reduces the need for frequent maintenance and contributes to a more efficient production flow over time.

Highlights

- Strong and durable: PA6 is resistant to impact and abrasion, perfect for use in moving parts and machine components

- Flexible formability: The material can be easily adapted to unique geometries and complex designs

- Excellent wear resistance: The component retains its quality and function over a longer period of time

- Chemical resistance: Resists a wide range of chemicals, suitable for environments where corrosion may be a problem

Contact us

Scanco AS is ready to help you find the right solution, no matter how complex your needs may be. Please contact us for more information about our range of PA6products, or to discuss your specific requirements. We are your trusted partner in engineering plastics and offer guidance throughout the entire process.

T

custom machined parts

If you need customized components, we can produce machined parts to your specifications. Our experienced team works closely with you to deliver solutions that are exactly right for your project. Contact us easily through our contact form to get started with your needs today.